Electrionics&electrics

电子电器

Home appliances

Commercial appliances

Outdoor lighting

Indoor lighting

Electronic equipment

Electric equipment

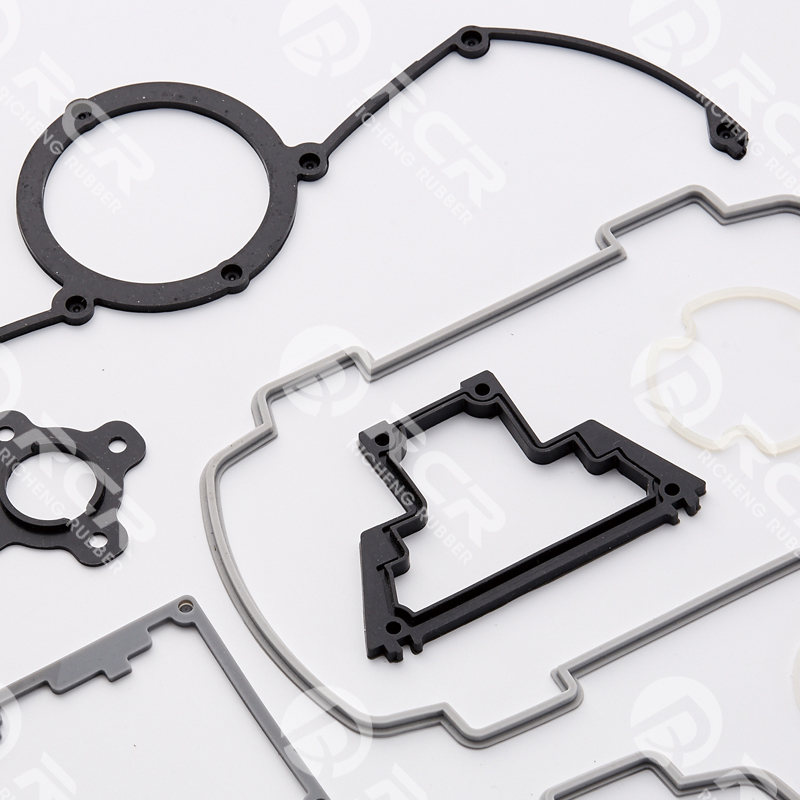

Silicone rubber extruded seals

Silicone rubber, a kind of polymer material, is featured with nontoxicity, environment-friendliness, high-and low-temperature resistance, ageing resistance, weather resistance. Our company is engaged in customized production of all kinds of silicone rubber sealing strips in U-type, P-type, E-type, D-type, L-type and other irregular type, with the sealing performance meeting the sealing requirements of all kinds of electronic appliances and lighting equipment.

Raw material | Silicone rubber | |||||

Manufacturing process | Certification | Hardness (Shore A) | Tensile strength (Mpa) | Elongation at break (%) | Tearing strength (kN/mm) | Operating temperature range (℃) |

Extrusion solid | ROHS FDA REACH, etc. | 30-85 | 6-10 | 250-700 | 16-50 | -100-315 |

Extrusion foaming | ROHS FDA REACH, etc. | 20-45 | 1.5-4.5 | 200-400 | 10-20 | -55-315 |

■The above data are data of general products under lab conditions, with test conditions beingDCBP, 1.2%, 110℃X10min

■In addition to data in the above chart, our company can also provide products with better performance according to customer's requirements. Please contact our marketing personnel for further information.

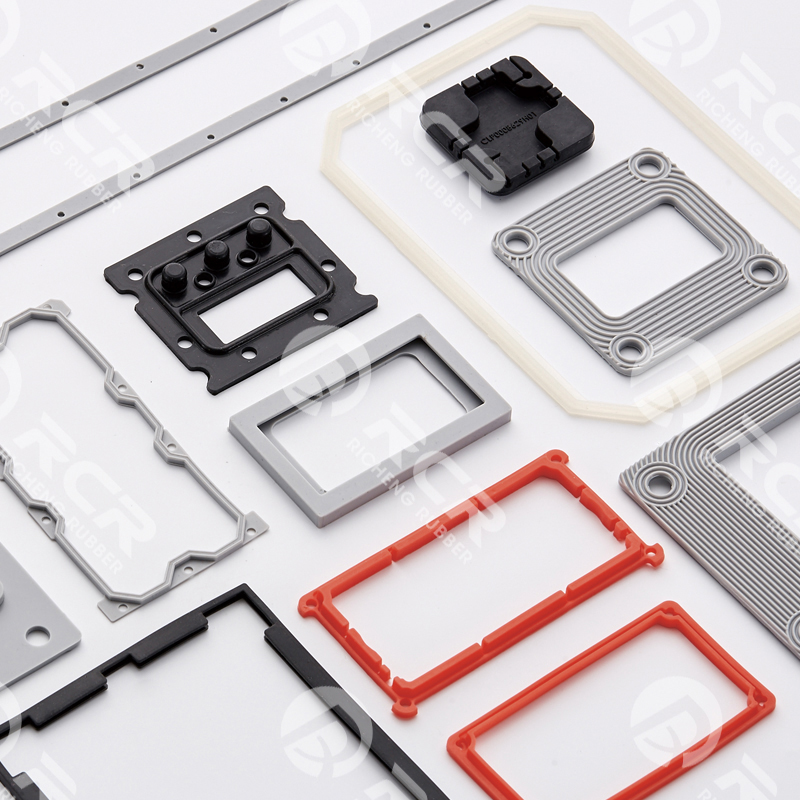

Silicone rubber molded structural parts

Silicone rubber has been widely applied to the electronic appliances field due to its excellent performance. Our company is engaged in customized production of all kinds of silicone rubber molded structural parts in square, round and other irregular shapes. In addition to achieving the general properties, our company can also produce other silicone rubber products with electrical conductivity, thermal conductivity, fire resistance and other special properties.

Raw material | Silicone rubber | |||||

Manufacturing process | Certification | Hardness(Shore A) | Tensile strength (Mpa) | Elongation at break (%) | Tearing strength (kN/mm) | 使用温度范围(℃) |

Molding solid | ROHS FDA REACH, etc. | 15-90 | 6-10 | 150-800 | 18-50 | -100-315 |

Molding foaming | ROHS FDA REACH, etc. | 10-45 | 1.5-4.5 | 250-500 | 10-20 | -55-315 |

■The above data are data of general products under lab conditions, with test conditions beingDBPH with the concentration of 50%, 1.2%,170℃X10min,

■In addition to data in the above chart, our company can also provide products with better performance according to customer's requirements. Please contact our marketing personnel for further information.

- Solid non-hollow seal

- Solid hollow seal

- Foam hollow seal

- Foam non-hollow seal

- Composite seal

- Adhesive seal

- Square silicon rubber molding

- Profiled silicon rubber molded

- Round silicon rubber molding

- Solid bonded seal

- Foam adhesive seal

- Other molded electronics

- Conductive silicone rubber

- Other molded electronics

We introduced the “CO-DESIGN” concept

It means joint development and design of rubber products with customers through communication,

so as to better realize product functions.

关注官方微信

关注官方微信 阿里巴巴

阿里巴巴